Phone:+ 86-769-83341628

Fax:+ 86-769-83342028

Email: emeidg@emeigroup.com

Website: http://www.emeigroup.com.cn/

Electrical applications

Thermosetting materials are widely used in medium and low-voltage electrical products, and their unique performance advantages make them an indispensable part of electrical manufacturing. The following is a specific analysis of the application of thermosetting materials in medium and low-voltage electrical products:

I. Characteristics of Thermosetting Materials

Thermosetting materials are a class of materials that can cure upon heating and maintain shape and dimensional stability. Their main characteristics include:

Heat Resistance: Capable of maintaining good performance stability even in high-temperature environments.

Flame Retardancy: Able to slow down the spread of fire in emergencies such as fires, enhancing the safety of electrical equipment.

Dimensional Stability: Minimal dimensional changes after molding, helping to maintain the precision and reliability of electrical products.

Mechanical Strength: High tensile, compressive, and impact resistance.

Electrical Performance: Excellent electrical insulation and dielectric properties, suitable for insulating components in electrical products.

II. Application of Thermosetting Materials in Medium and Low-Voltage Electrical Products

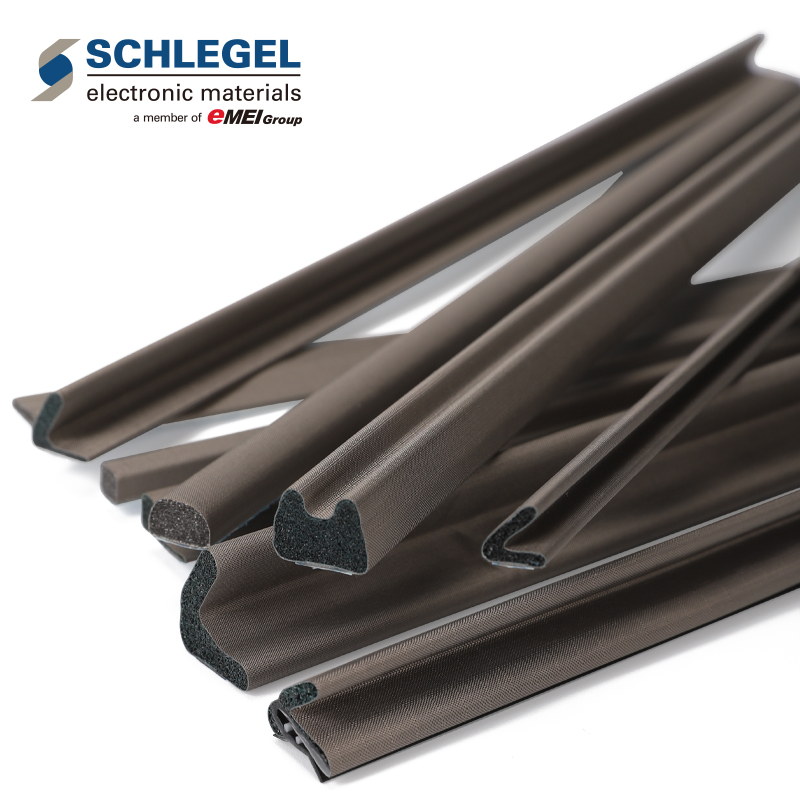

Insulating Components:

Many key components in medium and low-voltage electrical products, such as insulating plates, insulating sleeves, and insulators, are made from thermosetting materials. These components play a crucial role in isolating circuits, preventing electric shocks, and avoiding short circuits during the operation of electrical products.

Structural Support Components:

The high mechanical strength and dimensional stability of thermosetting materials make them an ideal choice for structural support components in electrical products. These components provide support and fixation for other parts, ensuring the overall stability and reliability of electrical products.

For example, components such as enclosures, brackets, and bases made from thermosetting plastics not only possess sufficient mechanical strength but also maintain stable performance in harsh environments.

Functional Components:

Some components with specific functions in electrical products are also made from thermosetting materials. These components play critical roles in the operation of electrical products, such as contacts and switches.

For instance, the application of thermosetting plastics in relay products is increasingly widespread, as their excellent mechanical and electrical properties make relay products more reliable and durable.

In summary, thermosetting materials are extensively and significantly applied in medium and low-voltage electrical products. Their unique performance advantages make them indispensable in electrical manufacturing. With the continuous advancement of technology and the ongoing upgrades of electrical products, the application prospects of thermosetting materials in electrical products will become even broader.