-

-

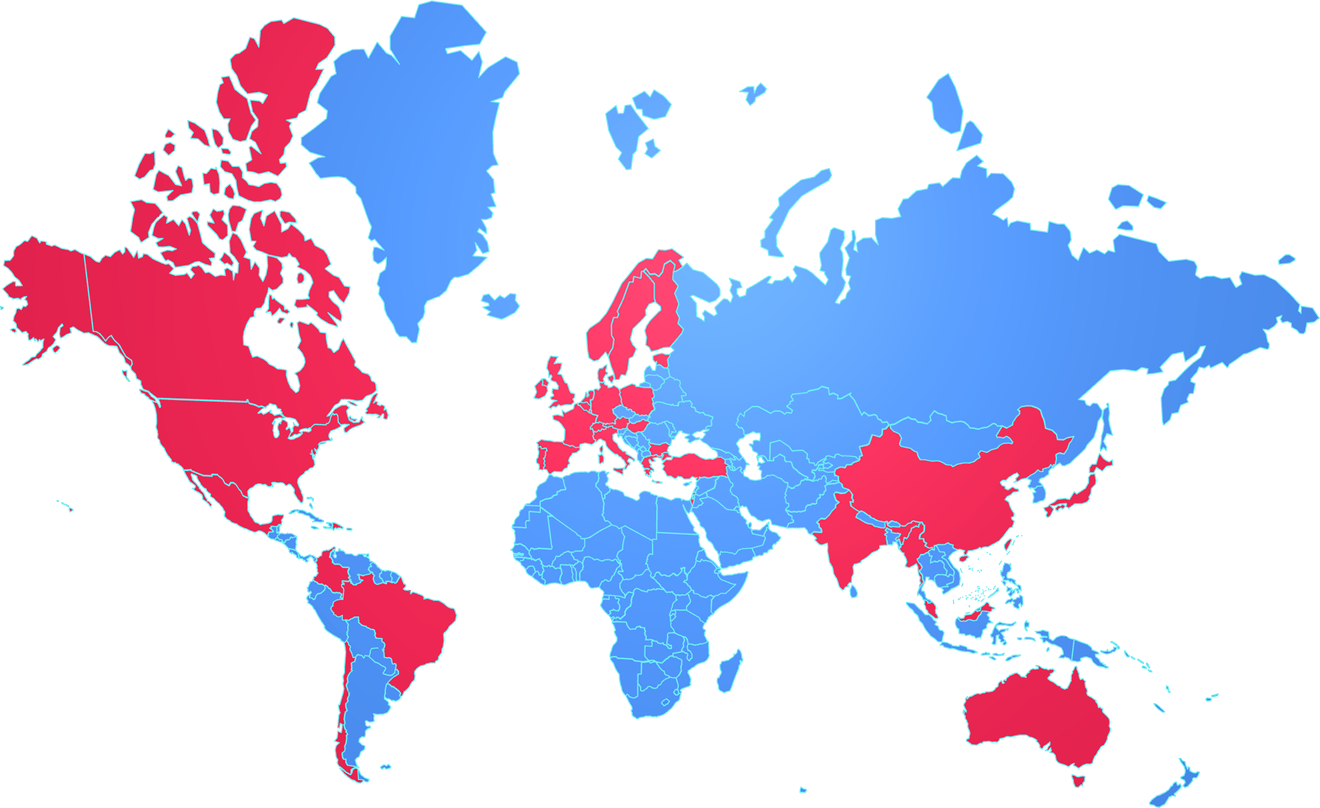

We were founded in 1992 as a Trading Company and distributor of Electronic components. In 1996, we started our fabrication and repacking sub-contracting house in Dongguan. From 2004, we consolidated our name as Emei Group and became a Leading manufacturer and supplier of EMI Gaskets, TIMs, Compounds and Adhesives, Bulk Molding Compounds and Specialty Transformers. We have four Business units with strong R & D and Supporting team in Dongguan, China. We have sales offices and manufacturing facilities in North America, Belgium, Hong Kong, Shanghai, and Taiwan. We have distributors in the USA, Mexico, Europe, the Middle East, and Japan.

-

-

-

1992

• Founded as a Trading Company and built up our network in Electronic Market

Acquired a new 7000 sq ft office in Shatin

-

1999

• Distributed more than 30 brands

-

2002

• Achieved ISO 9001 version 2000 Certification

• Became the Preferred Converter of Roger USA

-

2004

• Acquired over 54000 Sq M Land and to build our own Plant in Dongguan

• Joint Venture Established with BMC Inc USA to manufacture and sales of Bulk Molding Compound

• Set up our 100% own Emei Component Dongguan Limited for Transformer and Coils manufacturing

• Set up our Shanghai and Taiwan office with secondary production facility

-

2006

• Grand Opening of our 37000 Sq M Emei Plant which can accommodate 1000 workers

• Became a recognized manufacturing brand in Electronic industry – a business partner of Flextronics, Titron, V Tech, Johnson, Truly, Elec & Elteck, Foxconn, Alcatel, IBM, Sanmina. Intel, Cooler Master, GE, Siemens and Whirlpool

-

2012

• 20th Anniversary Celebration in Dongguan with all the Partners, Government Officials, and our US, Belgium, Taiwan, Shanghai colleagues

-

2018

• Launched of our Schlegel BandSorb Microwave Absorber

-

2019

• Launch of Schlegel OpTIM Thermal Product

• Became a Member of Hong Kong Electronics Association

-

2021

• We were awarded High-tech Enterprise Identification

-

2022

• Celebrating 30th Anniversary in Electronics Industry

-

2025

• Obtain IATF 16949 certification

-

-

-

-

-

Conductive foamThermal conduction gap filling padPolyFab foam

-

Assembly of motor/stepper motorFlexible circuit/membrane switchMedical equipment

-

Surface mount transformerPower inductanceSingle switch power supply

-

Medium voltage electricalLow voltage electricalHousehold appliances

-

-

Emei Group

Low Voltage Electrical Application

BMC has been widely used in low voltage electrical application, such as low voltage circuit breakers, rotors, supports, etc. The following are the advantages of BMC in low voltage electrical application:

1. Excellent insulation performance: effectively isolating current to ensure the safety of electrical equipment

2. High mechanical strength: ensuring the safety of low voltage electrical equipment during operation

3. Dimensional stability: suitable for precise design of electrical equipment

4. Flame retardancy: It can slow down the spread of fire and improve the safety of electrical equipment in emergency situations such as fires

5. Cost effectiveness: Compared fiber glass reinforced – flame resistance thermoplastic, BMC has lower costs and better performance

6. Environmental adaptability: Good weather resistance, suitable for different environments

Formula Suggested: BMC 1412 / BMC 350 / BMC F4308 / BMC T14(20)

Add: No. 8 Qiaoxin Road, Qiaotou Town,

Tel:+ 86-769-83341628

Fax:+ 86-769-83342028

Email: emeidg@emeigroup.com

Website: http://www.emeigroup.com.cn