Phone:+ 86-769-83341628

Fax:+ 86-769-83342028

Email: emeidg@emeigroup.com

Website: http://www.emeigroup.com.cn/

Electronica equipment

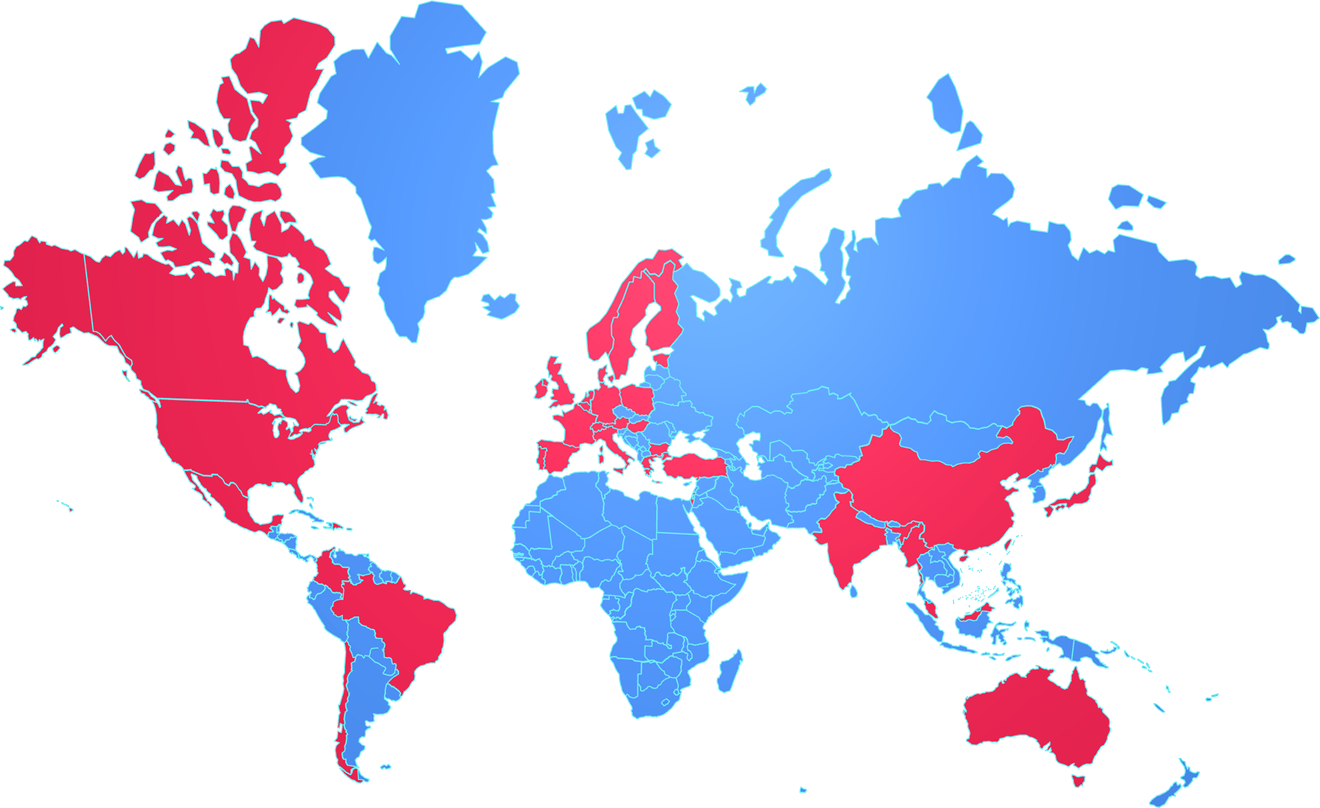

High-performance adhesives are widely used in the electronic device market, each possessing unique properties and advantages that provide essential support for the manufacturing, assembly, and maintenance of electronic devices. Below is a detailed analysis of the applications of these three types of adhesives in the electronic device market:

I. Application of UV Adhesive

UV adhesive (ultraviolet light-curing adhesive), as a fast-curing, environmentally friendly, and high-performance bonding agent, has extensive applications in the electronic device market. Its main applications include:

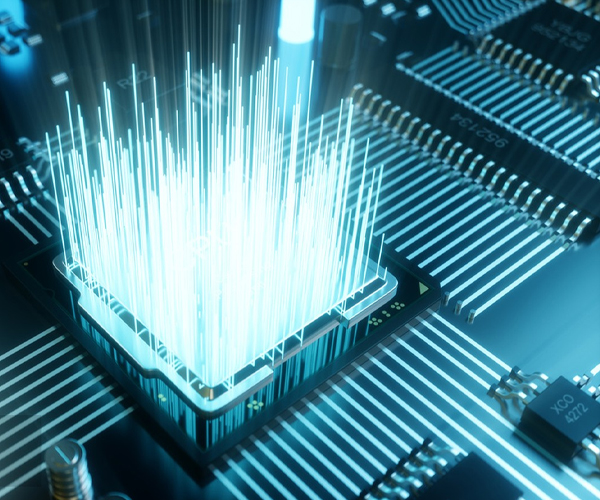

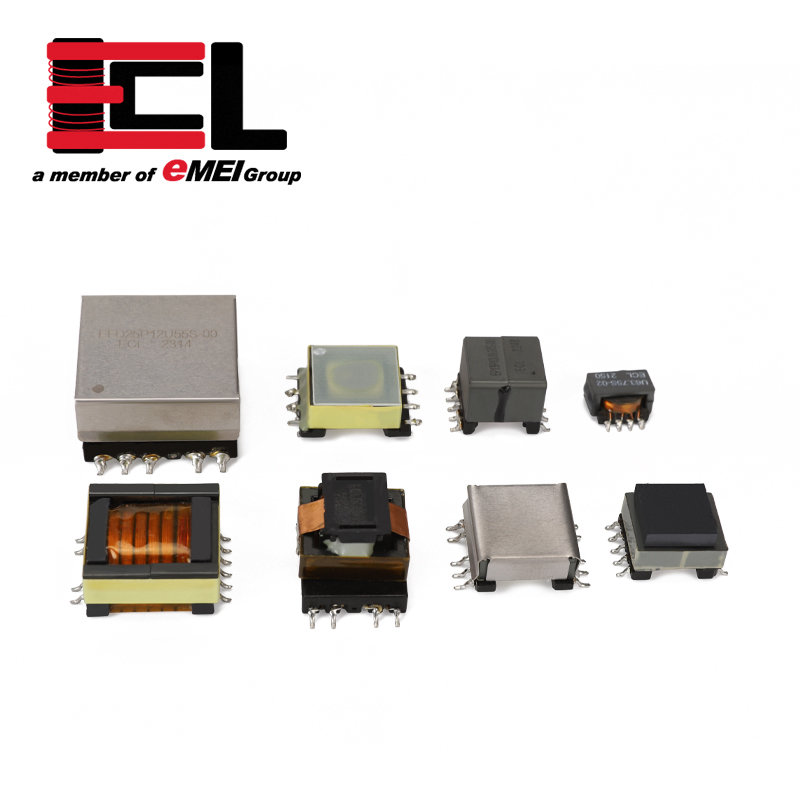

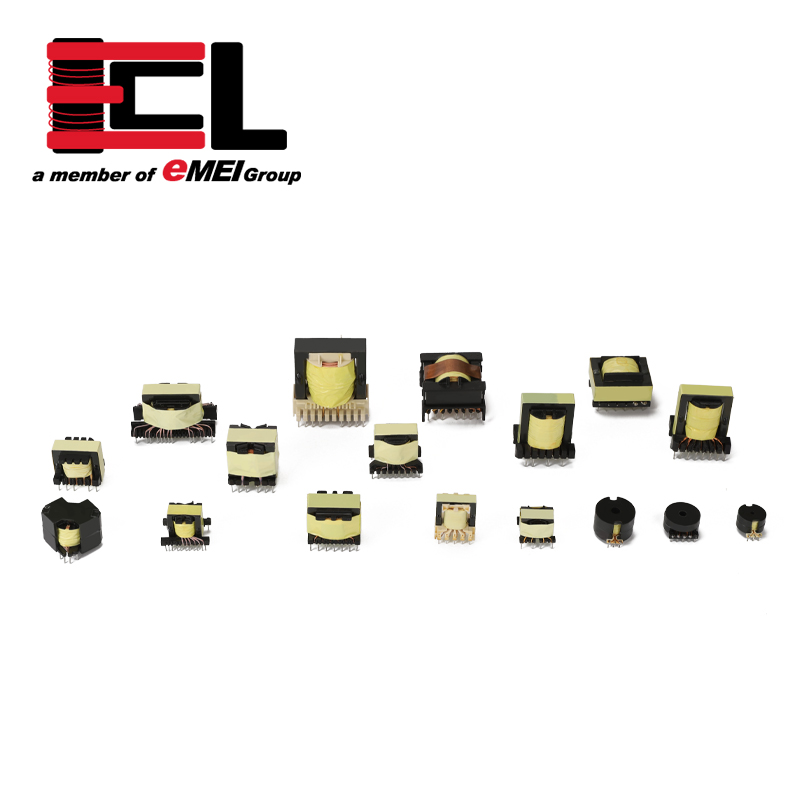

Component Fixation and Encapsulation: UV adhesive can cure rapidly, securely fixing electronic components such as resistors, capacitors, and inductors onto printed circuit boards (PCBs), while providing mechanical protection and electrical insulation. Additionally, UV adhesive is commonly used in the encapsulation process of electronic components to form a robust protective layer, preventing moisture, dust, and other contaminants from infiltrating.

Solder Joint Protection: In the manufacturing of connectors such as USB-C and Lightning connectors, a very small chip is mounted on the PCB via SMT, and equally tiny solder joints are formed on the terminals. To prevent damage to these solder joints during subsequent injection molding, UV adhesive with good adhesion can be used for solder joint protection and chip encapsulation.

PCB Conformal Coating: UV adhesives are the preferred material for PCB conformal coatings due to their fast curing time, excellent bonding properties, and ability to provide an even coating even on complex PCB geometries. This helps enhance the durability and stability of the PCB.

Variable Resistor and Capacitor Fixation: After adjusting variable resistors or capacitors, adhesive is needed for fixation. Our UV adhesive exerts minimal stress, capable of maintaining the accuracy of resistance and capacitance values over the long term. It can be applied in products such as laser head fixation and filter setting.

II. Application of Structural Adhesive

Structural adhesives are primarily used in the electronic device market to provide strong bonding strength and structural support. Their applications include:

Chip Encapsulation: In integrated circuit (IC) packaging processes, structural adhesive is used to secure and seal the connection between the IC chip and the substrate, providing mechanical support and protection. This helps ensure stable connections and reliable performance of the chip in complex environments.

Circuit Board Assembly: Structural adhesive can be used in the assembly process of circuit boards with other components, such as securing circuit boards inside device housings or connecting them to other circuit boards. Its strong bonding strength and durability contribute to the stability and reliability of the entire electronic device.

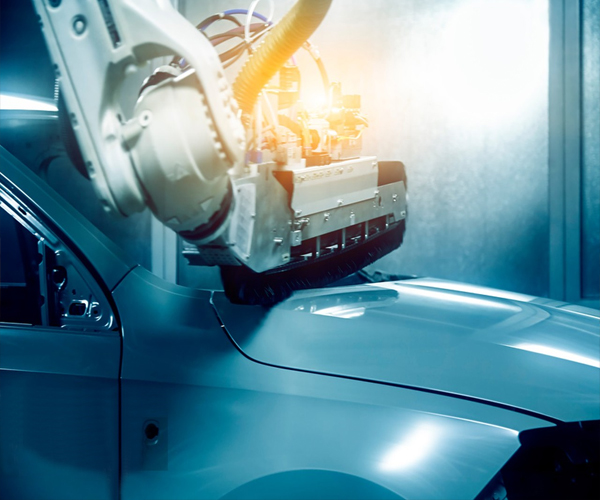

Wire Harness Fixation: In the stators of brushless motors, there are relatively fragile spot welds. High-temperature-resistant adhesive can be used for reinforcement to withstand subsequent rigorous vibration and drop tests.

III. Application of Conductive Adhesives and Inks

Conductive adhesive is a type of adhesive capable of conducting electricity, primarily composed of conductive particles, adhesive, and additives. In the electronic device market, the applications of conductive adhesives mainly include:

Circuit Connection: Conductive adhesive can act as a bridge on circuit boards, directly connecting two different electronic components. This connection method not only simplifies the manufacturing process of circuit boards but also improves circuit reliability and flexibility.

Touchscreen Fabrication: In the production of touchscreens, conductive adhesive can form conductive traces, enabling the physical connection between touch interactions and electronic actuators. Its high conductivity and excellent adhesion give touchscreens superior touch response and durability.

Chip Encapsulation: Conductive silver paste is commonly used in chip encapsulation processes, such as in LED packaging, IC packaging, and Chip-on-Board (COB) applications. Conductive silver adhesive can fix the chip to the substrate while providing good electrical conductivity. In addition to conductivity, silver adhesive can also act as a thermal interface material to transfer heat from the IC to the substrate, achieving heat dissipation.

In summary, UV adhesive, structural adhesive, and conductive adhesive each play vital roles in the electronic device market. Their applications not only enhance the manufacturing efficiency and performance of electronic devices but also reduce product costs and maintenance difficulties. With the continuous development of electronic technology, the application prospects of these three adhesives in the electronic device market will become even broader.