-

-

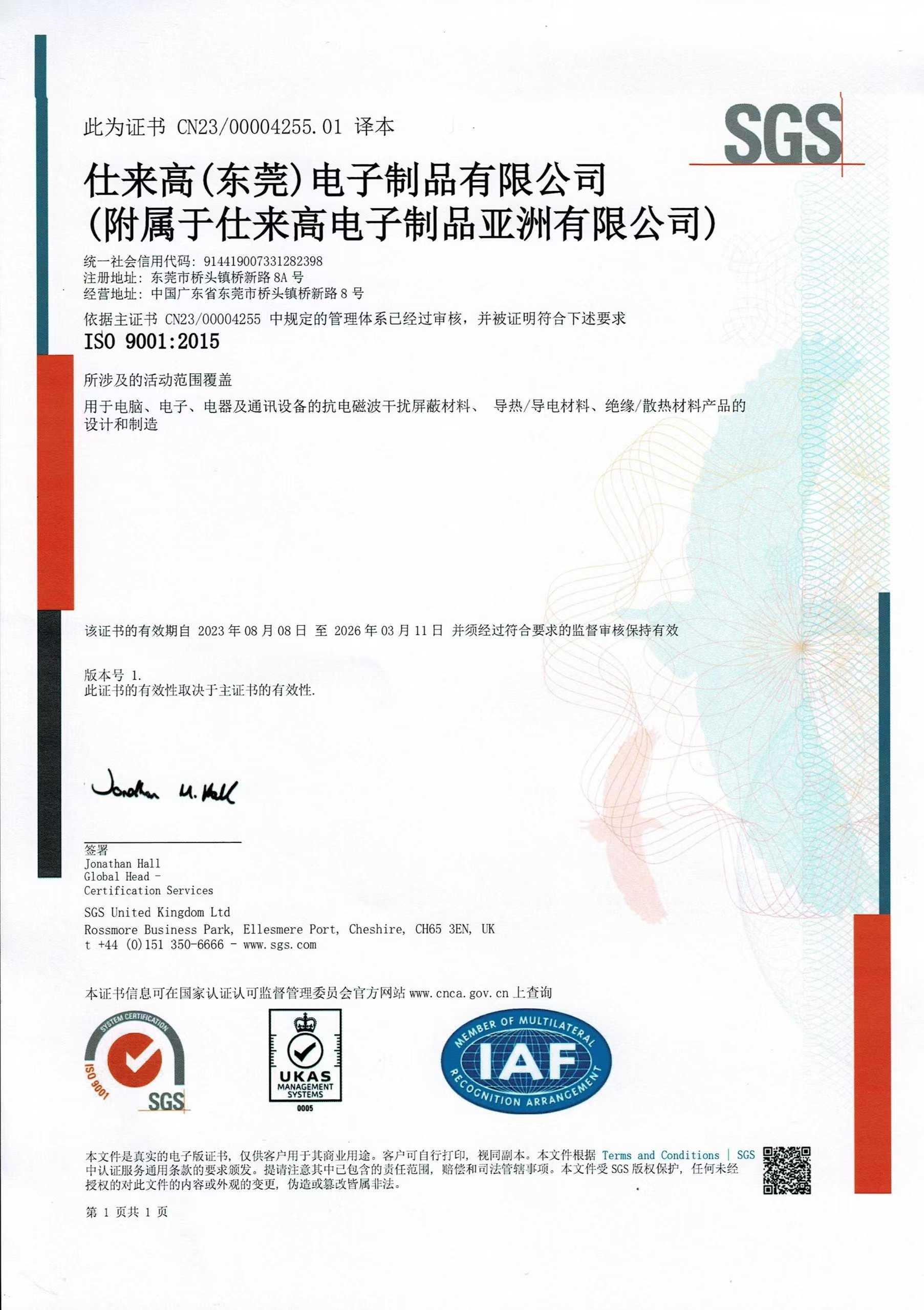

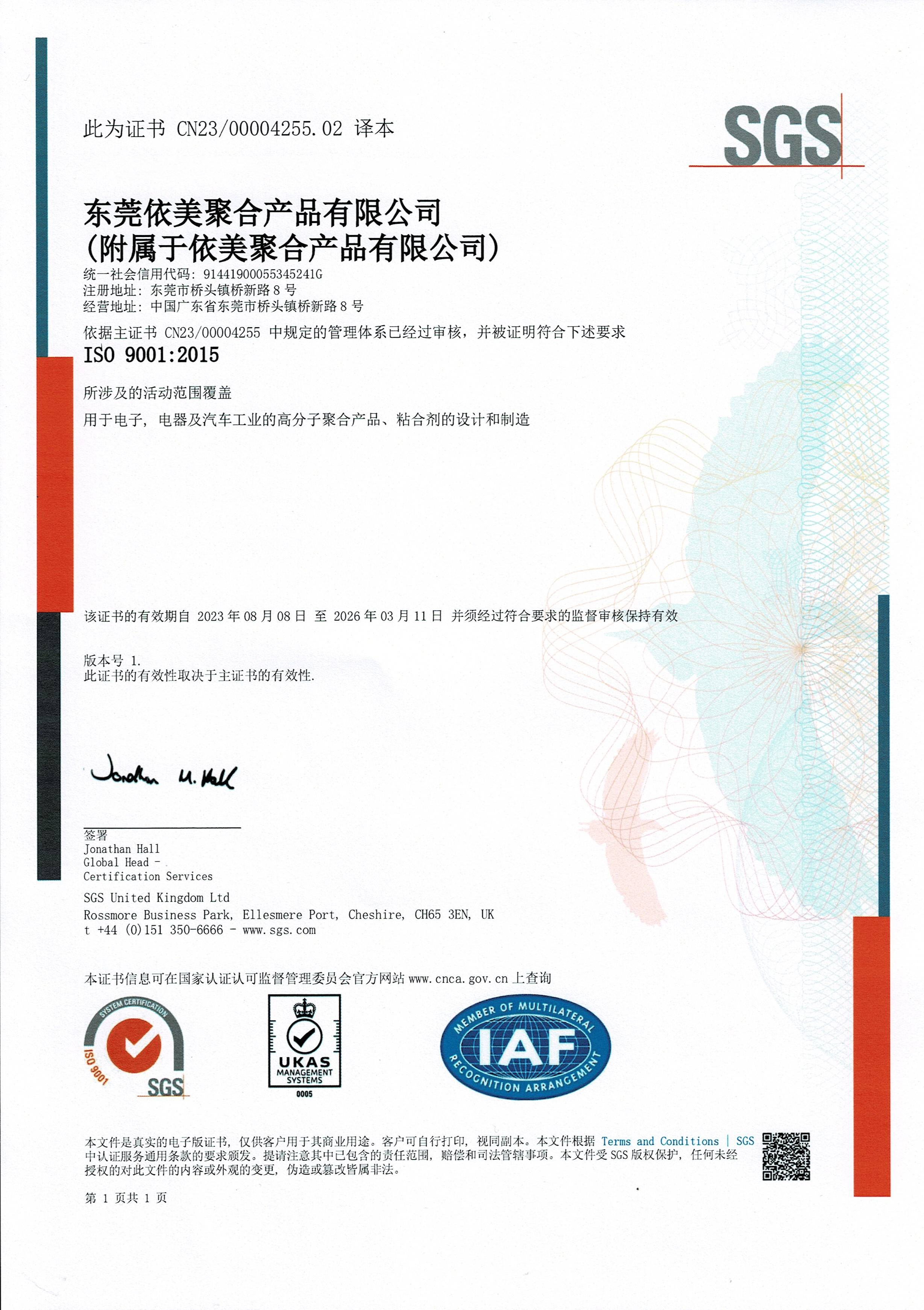

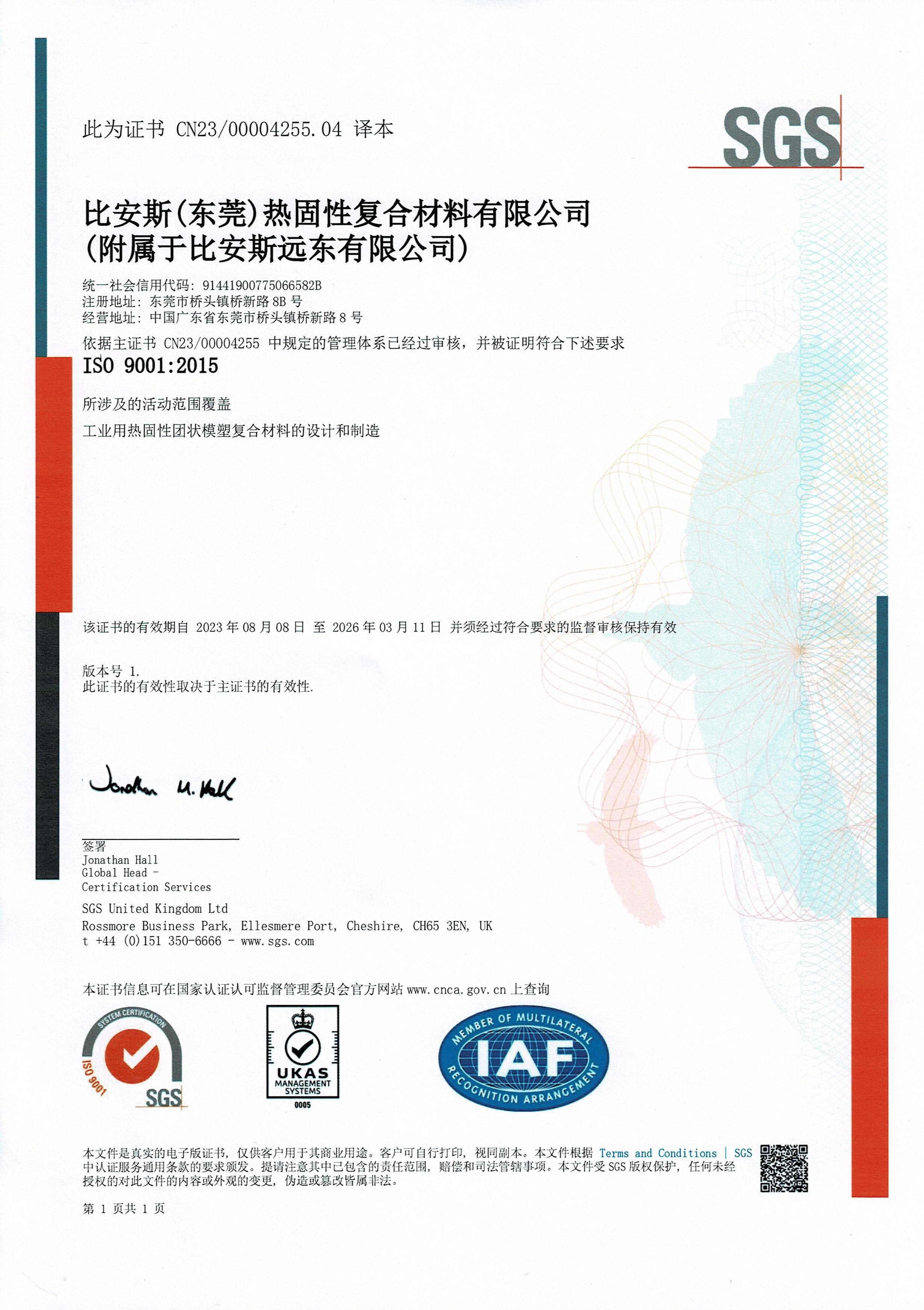

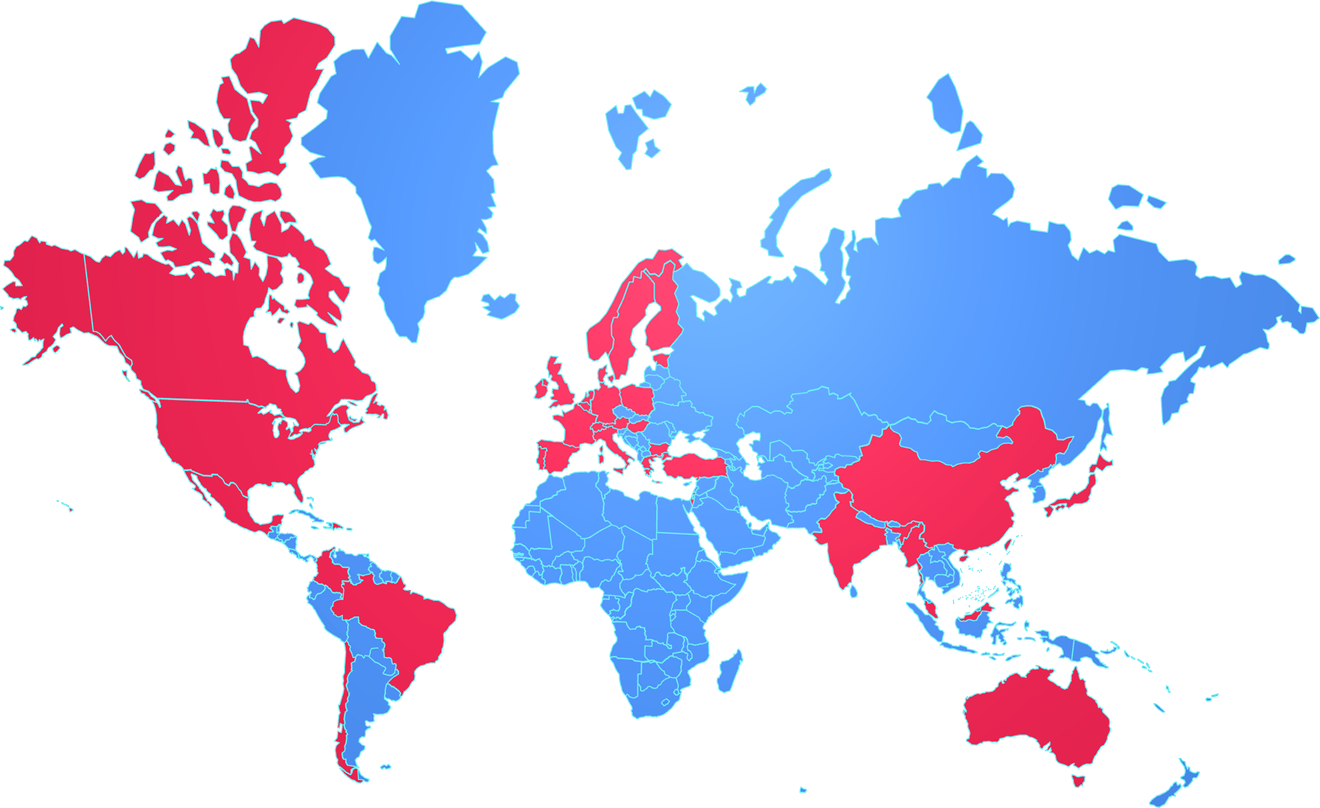

We were founded in 1992 as a Trading Company and distributor of Electronic components. In 1996, we started our fabrication and repacking sub-contracting house in Dongguan. From 2004, we consolidated our name as Emei Group and became a Leading manufacturer and supplier of EMI Gaskets, TIMs, Compounds and Adhesives, Bulk Molding Compounds and Specialty Transformers. We have four Business units with strong R & D and Supporting team in Dongguan, China. We have sales offices and manufacturing facilities in North America, Belgium, Hong Kong, Shanghai, and Taiwan. We have distributors in the USA, Mexico, Europe, the Middle East, and Japan.

-

-

-

1992

• Founded as a Trading Company and built up our network in Electronic Market

Acquired a new 7000 sq ft office in Shatin

-

1999

• Distributed more than 30 brands

-

2002

• Achieved ISO 9001 version 2000 Certification

• Became the Preferred Converter of Roger USA

-

2004

• Acquired over 54000 Sq M Land and to build our own Plant in Dongguan

• Joint Venture Established with BMC Inc USA to manufacture and sales of Bulk Molding Compound

• Set up our 100% own Emei Component Dongguan Limited for Transformer and Coils manufacturing

• Set up our Shanghai and Taiwan office with secondary production facility

-

2006

• Grand Opening of our 37000 Sq M Emei Plant which can accommodate 1000 workers

• Became a recognized manufacturing brand in Electronic industry – a business partner of Flextronics, Titron, V Tech, Johnson, Truly, Elec & Elteck, Foxconn, Alcatel, IBM, Sanmina. Intel, Cooler Master, GE, Siemens and Whirlpool

-

2012

• 20th Anniversary Celebration in Dongguan with all the Partners, Government Officials, and our US, Belgium, Taiwan, Shanghai colleagues

-

2018

• Launched of our Schlegel BandSorb Microwave Absorber

-

2019

• Launch of Schlegel OpTIM Thermal Product

• Became a Member of Hong Kong Electronics Association

-

2021

• We were awarded High-tech Enterprise Identification

-

2022

• Celebrating 30th Anniversary in Electronics Industry

-

2025

• Obtain IATF 16949 certification

-

-

-

-

-

Conductive foamThermal conduction gap filling padPolyFab foam

-

Assembly of motor/stepper motorFlexible circuit/membrane switchMedical equipment

-

Surface mount transformerPower inductanceSingle switch power supply

-

Medium voltage electricalLow voltage electricalHousehold appliances

-

-

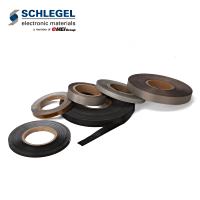

Emei Group

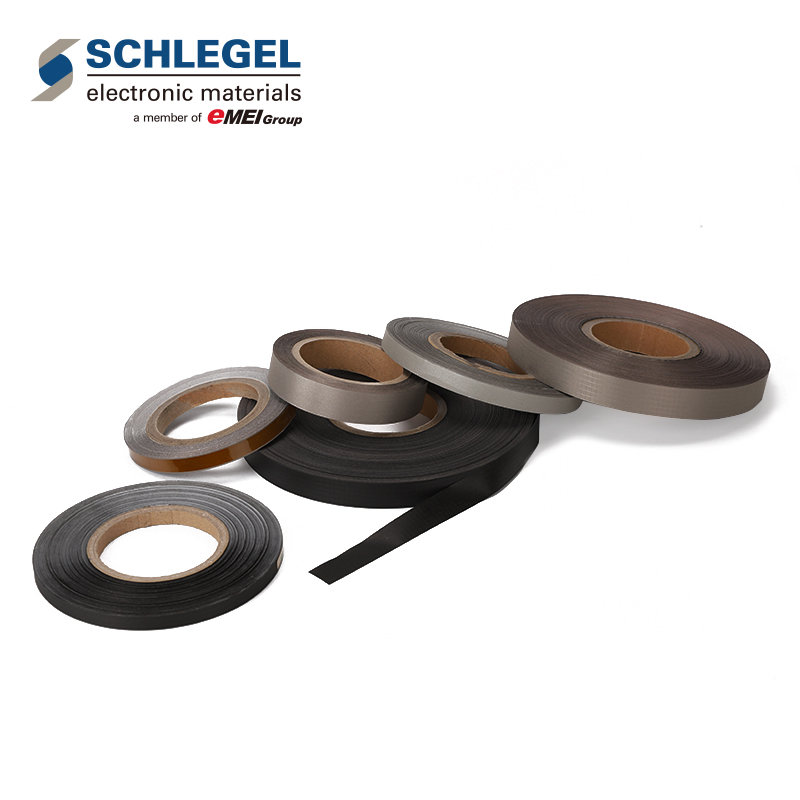

Conductive Tapes

More flexibility, higher conductivity, and easier installation

Schlegel Electronic Materials (SEM) expanded line of Conductive Tapes meets the customer needs for flexibility, higher conductivity, and easier installation. They are available with conductive and non-conductive adhesives and in a wide range of widths.

Typical applications include cable Shielding terminations and joining metal panels together at the seams of an enclosure. Foil tapes are a cost-effective shielding solution for a wide range of uses. They can be particularly useful during the development and test phases of projects to be used as “fixes” for EMI problems.

SEM’s masked conductive tapes are also available and can be used as a gasket substrate on painted or stove enameled enclosures.

Also available are special purpose adhesive tapes to include:

Pressure sensitive adhesive die-cuts

High-tack adhesive die-cuts

Low residueadhesive die-cuts

Silicone adhesive die-cuts

Insulation adhesive die-cuts

Heat resistive adhesive die-cuts

SEM’s Conductive Tapes feature superior shear strength, 7.6 kPa (72+ hours @ 1.1 psi) in accordance to (PSTC #7) ASTM D 3654, and peel strength, 10.2 N/2.5 cm. (36.07 oz/inch width) in accordance to PSTC #1) ASTM D 3330, when compared to other EMI shielding tapes. This is made possible by a unique, cross-linking acrylic based, conductive Pressure Sensitive Adhesive (PSA) that also allows the tapes to be designed into higher temperature applications. The PSA is fire-rated to UL 510, and excessive pressure is not required for application to the end unit. There is now an easy-to-apply tape to fit most every EMI shielding design need.

Add: No. 8 Qiaoxin Road, Qiaotou Town,

Tel:+ 86-769-83341628

Fax:+ 86-769-83342028

Email: emeidg@emeigroup.com

Website: http://www.emeigroup.com.cn