-

-

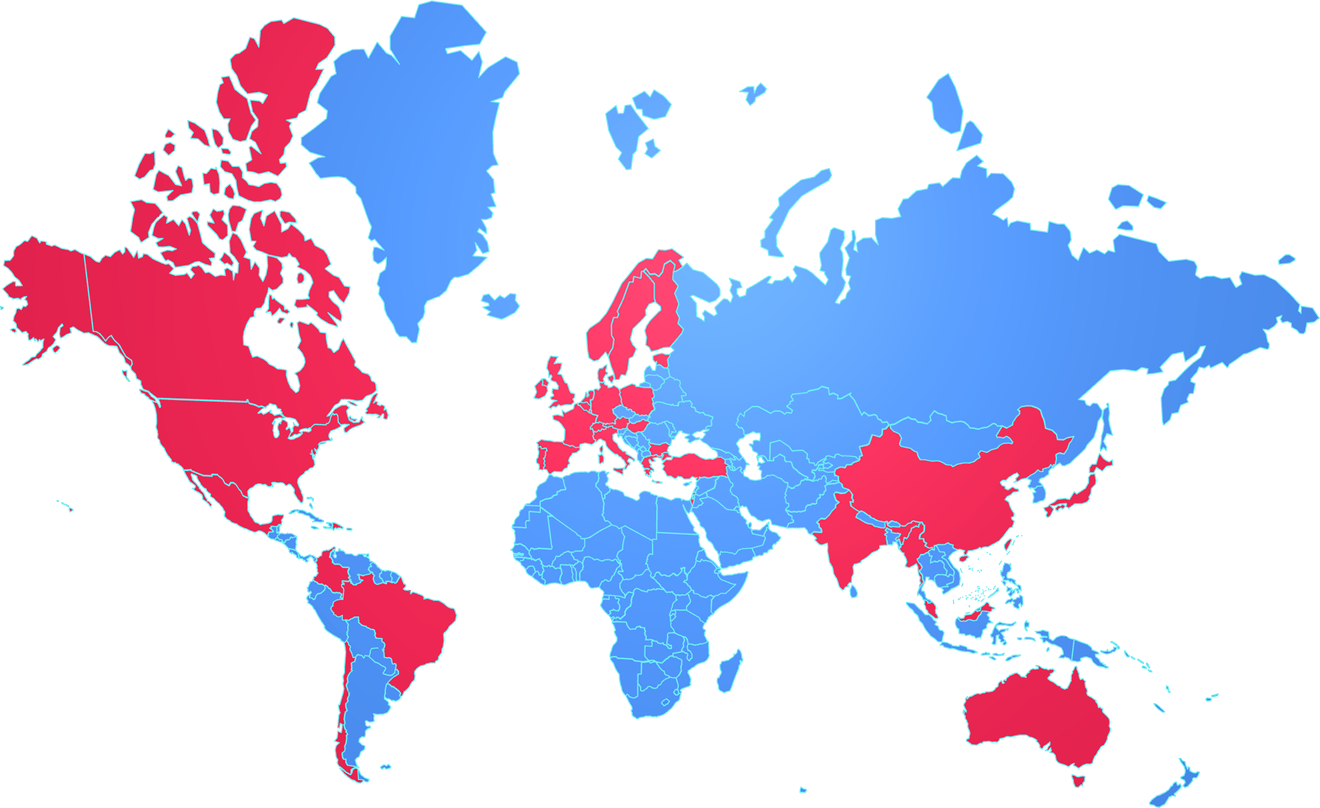

We were founded in 1992 as a Trading Company and distributor of Electronic components. In 1996, we started our fabrication and repacking sub-contracting house in Dongguan. From 2004, we consolidated our name as Emei Group and became a Leading manufacturer and supplier of EMI Gaskets, TIMs, Compounds and Adhesives, Bulk Molding Compounds and Specialty Transformers. We have four Business units with strong R & D and Supporting team in Dongguan, China. We have sales offices and manufacturing facilities in North America, Belgium, Hong Kong, Shanghai, and Taiwan. We have distributors in the USA, Mexico, Europe, the Middle East, and Japan.

-

-

-

1992

• Founded as a Trading Company and built up our network in Electronic Market

Acquired a new 7000 sq ft office in Shatin

-

1999

• Distributed more than 30 brands

-

2002

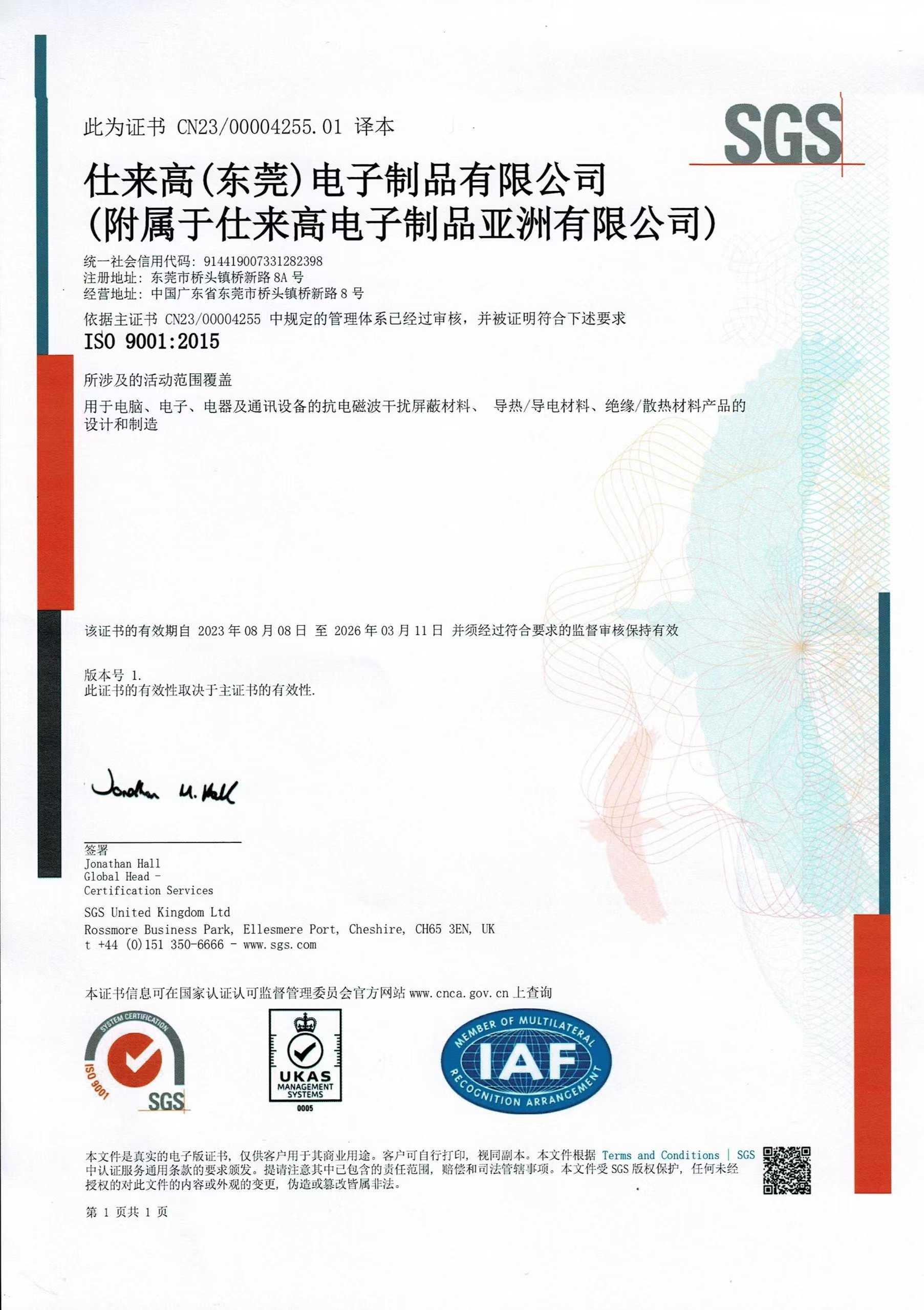

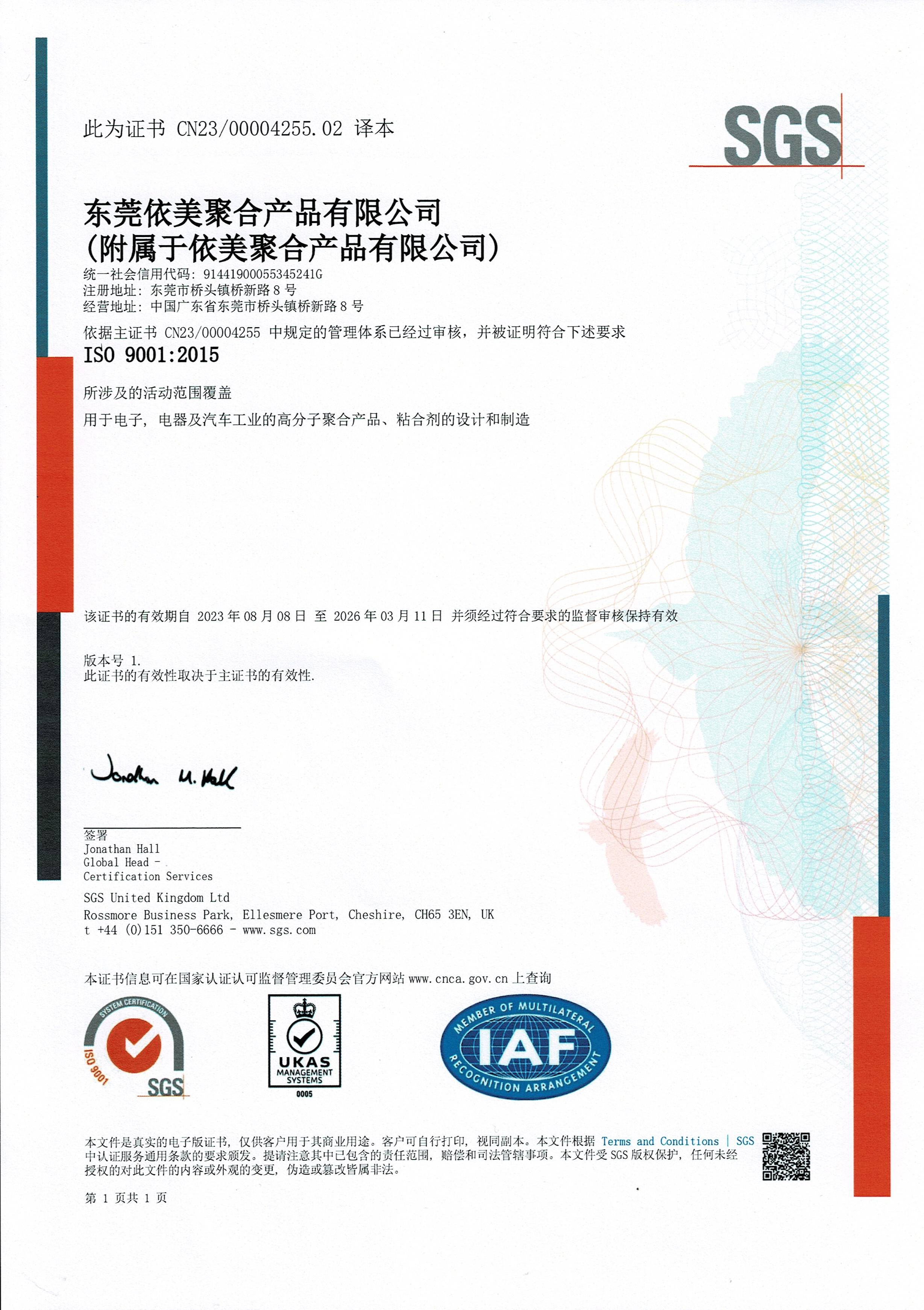

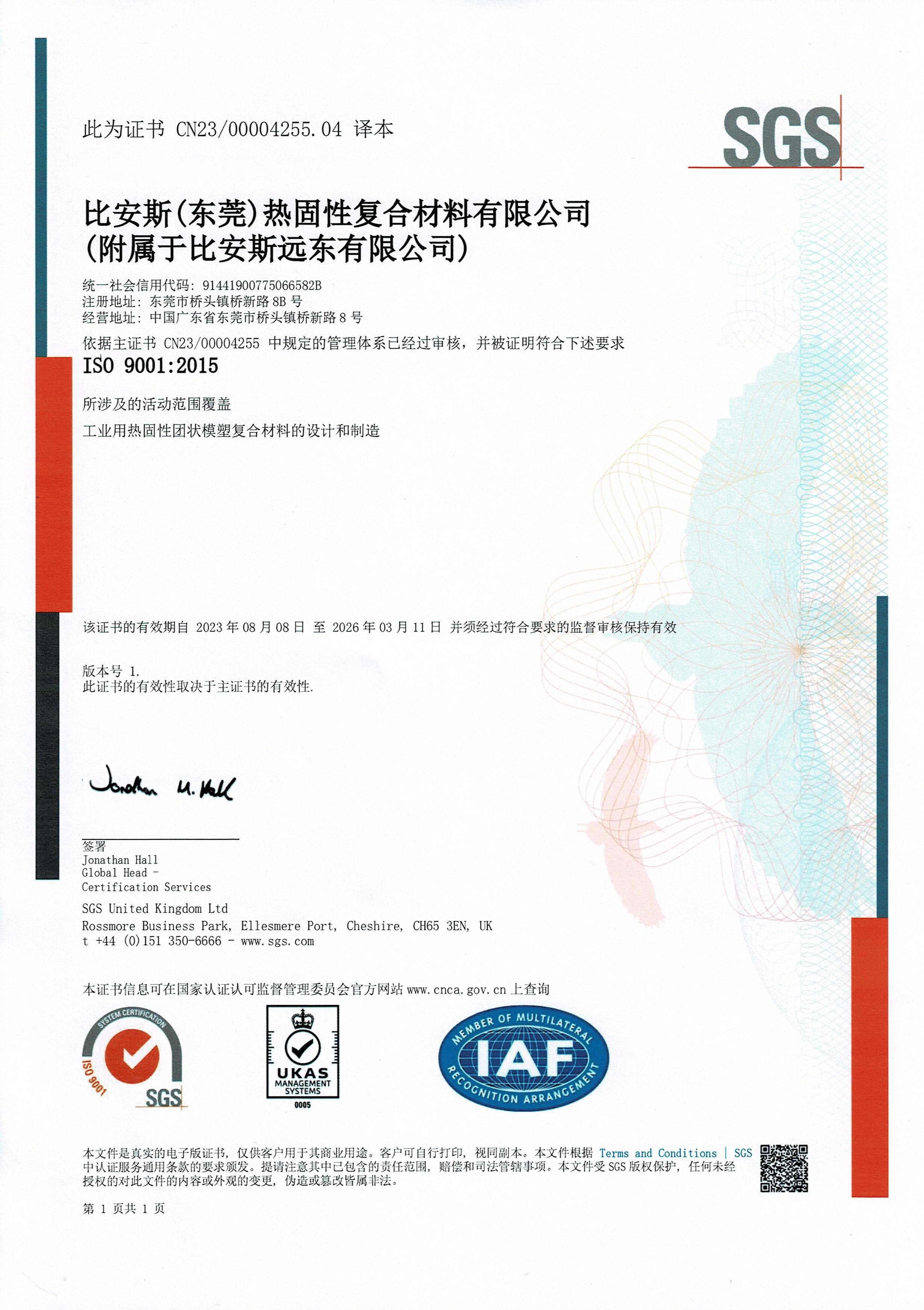

• Achieved ISO 9001 version 2000 Certification

• Became the Preferred Converter of Roger USA

-

2004

• Acquired over 54000 Sq M Land and to build our own Plant in Dongguan

• Joint Venture Established with BMC Inc USA to manufacture and sales of Bulk Molding Compound

• Set up our 100% own Emei Component Dongguan Limited for Transformer and Coils manufacturing

• Set up our Shanghai and Taiwan office with secondary production facility

-

2006

• Grand Opening of our 37000 Sq M Emei Plant which can accommodate 1000 workers

• Became a recognized manufacturing brand in Electronic industry – a business partner of Flextronics, Titron, V Tech, Johnson, Truly, Elec & Elteck, Foxconn, Alcatel, IBM, Sanmina. Intel, Cooler Master, GE, Siemens and Whirlpool

-

2012

• 20th Anniversary Celebration in Dongguan with all the Partners, Government Officials, and our US, Belgium, Taiwan, Shanghai colleagues

-

2018

• Launched of our Schlegel BandSorb Microwave Absorber

-

2019

• Launch of Schlegel OpTIM Thermal Product

• Became a Member of Hong Kong Electronics Association

-

2021

• We were awarded High-tech Enterprise Identification

-

2022

• Celebrating 30th Anniversary in Electronics Industry

-

2025

• Obtain IATF 16949 certification

-

-

-

-

-

Conductive foamThermal conduction gap filling padPolyFab foam

-

Assembly of motor/stepper motorFlexible circuit/membrane switchMedical equipment

-

Surface mount transformerPower inductanceSingle switch power supply

-

Medium voltage electricalLow voltage electricalHousehold appliances

-

-

Emei Group

Low Voltage Electrical Application

BMC 在低压电气产品中得到了广泛应用,如低压断路器、转轴、支架等,以下为 BMC 在低压电气产品的优势:

1. 卓越的绝缘性能:有效隔离电流,确保电气设备的安全运行

2. 高机械强度:保证低压电气设备运行时的安全性

3. 尺寸稳定性:适合电气设备的精确设计

4. 阻燃性:能够在火灾等紧急情况下减缓火势蔓延,提高电气设备的安全性

5. 成本效益:相对于玻纤增强的阻燃热塑料,BMC成本更低,性能更好

6. 环境适应性:良好的耐候性,适合在恶劣环境下使用

常用配方:BMC 1412 / BMC 350 / BMC F4308 / BMC T14(20)

Add: No. 8 Qiaoxin Road, Qiaotou Town,

Tel:+ 86-769-83341628

Fax:+ 86-769-83342028

Email: emeidg@emeigroup.com

Website: http://www.emeigroup.com.cn