-

-

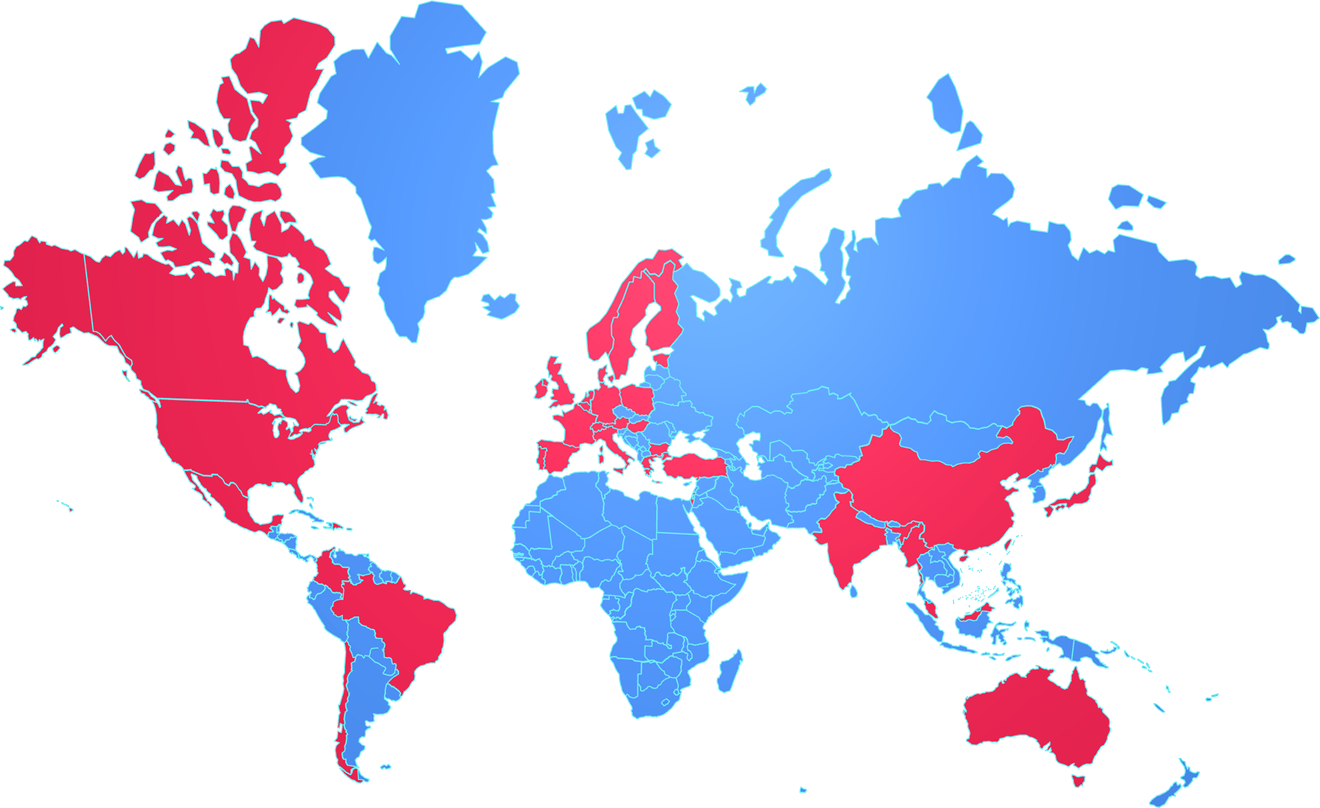

We were founded in 1992 as a Trading Company and distributor of Electronic components. In 1996, we started our fabrication and repacking sub-contracting house in Dongguan. From 2004, we consolidated our name as Emei Group and became a Leading manufacturer and supplier of EMI Gaskets, TIMs, Compounds and Adhesives, Bulk Molding Compounds and Specialty Transformers. We have four Business units with strong R & D and Supporting team in Dongguan, China. We have sales offices and manufacturing facilities in North America, Belgium, Hong Kong, Shanghai, and Taiwan. We have distributors in the USA, Mexico, Europe, the Middle East, and Japan.

-

-

-

1992

• Founded as a Trading Company and built up our network in Electronic Market

Acquired a new 7000 sq ft office in Shatin

-

1999

• Distributed more than 30 brands

-

2002

• Achieved ISO 9001 version 2000 Certification

• Became the Preferred Converter of Roger USA

-

2004

• Acquired over 54000 Sq M Land and to build our own Plant in Dongguan

• Joint Venture Established with BMC Inc USA to manufacture and sales of Bulk Molding Compound

• Set up our 100% own Emei Component Dongguan Limited for Transformer and Coils manufacturing

• Set up our Shanghai and Taiwan office with secondary production facility

-

2006

• Grand Opening of our 37000 Sq M Emei Plant which can accommodate 1000 workers

• Became a recognized manufacturing brand in Electronic industry – a business partner of Flextronics, Titron, V Tech, Johnson, Truly, Elec & Elteck, Foxconn, Alcatel, IBM, Sanmina. Intel, Cooler Master, GE, Siemens and Whirlpool

-

2012

• 20th Anniversary Celebration in Dongguan with all the Partners, Government Officials, and our US, Belgium, Taiwan, Shanghai colleagues

-

2018

• Launched of our Schlegel BandSorb Microwave Absorber

-

2019

• Launch of Schlegel OpTIM Thermal Product

• Became a Member of Hong Kong Electronics Association

-

2021

• We were awarded High-tech Enterprise Identification

-

2022

• Celebrating 30th Anniversary in Electronics Industry

-

2025

• Obtain IATF 16949 certification

-

-

-

-

-

Conductive foamThermal conduction gap filling padPolyFab foam

-

Assembly of motor/stepper motorFlexible circuit/membrane switchMedical equipment

-

Surface mount transformerPower inductanceSingle switch power supply

-

Medium voltage electricalLow voltage electricalHousehold appliances

-

-

Emei Group

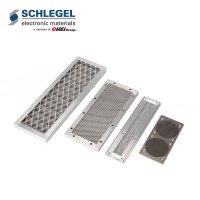

Honeycomb Vent Panel

As the originator of the fabric-clad foam EMI shielding technology, Schlegel EMI is the industry’s most trusted name. We continue to set the standard for quality and innovation, designing advanced solutions for a wide range of applications. And our worldwide locations ensure that you get what you need when you need it.

Modern electronic equipment often requires EMI Gaskets to avoid radiating EMI/RFI susceptibility to outside sources of EMI/RFI. Maintaining electromagnetic compatibility can be an increasing challenge for today’s electronic and electrical product designers.

Schlegel Electronic Materials, Inc. (SEM), the preeminent manufacturer of fabric over foam EMI shielding products for the computer, telecommunications, and electronic industries, offers a full range of EMI shielding products–including gaskets, I/O backplane shielding gaskets, and highly conductive envelopes, tapes and laminates. SEM is proud to introduce a complete line of quality honeycomb vent panels. Adding vent panels to SEM’s extensive portfolio of shielding products allows SEM to be your exclusive EMI shielding supplier to help you meet or exceed your global requirements for electromagnetic compatibility (EMC).

We use 5052-grade aluminum foil, a lightweight material offering superior strength and corrosion resistance over commercial-grade aluminum foils. It meets all the requirements of MIL-C- 7438. This material is used to manufacture aircraft floors & wing edges, missile wings, helicopter rotor blades, etc, so quality and repeatability are assured. Currently, we have seven frame styles available. To keep down production costs, vent panels made with styles 1701, 1703, 1705, 1706 & 1707 are normally supplied with three corners notched and the 4th joined corner welded. All four corners of the panel can be supplied fully welded if required. Frame styles 1702 & 1704 are always supplied with fully welded corners.

We can supply all frame styles with a conductive gasket to provide the best electrical contact between the frame and mating metal surface.

Standard tolerances for overall Finished Vent Dimensions are +/- 0.8mm

Standard tolerances on Hole Centres are +/- 0.4mm

Typical corner radii on frame styles 1701, 1703, 1705, 1706 & 1707 are R3.0mm

The standard finish for aluminium vent panels is SemPas , it fully meets the RoHS directive and replaces Alocrom 1200. This in-house process applies a permanganate passivation which is a chromate free, inorganic and non toxic coating. The process produces a dense, uniform coating consisting of aluminium and reduced manganese oxides giving a golden yellow colour to the surface. The surface finish is conductive with a low contact resistance equalling Alocrom 1200. It also meets all requirements of MIL-C-5541E for corrosion and electrical conductivity

Add: No. 8 Qiaoxin Road, Qiaotou Town,

Tel:+ 86-769-83341628

Fax:+ 86-769-83342028

Email: emeidg@emeigroup.com

Website: http://www.emeigroup.com.cn