-

-

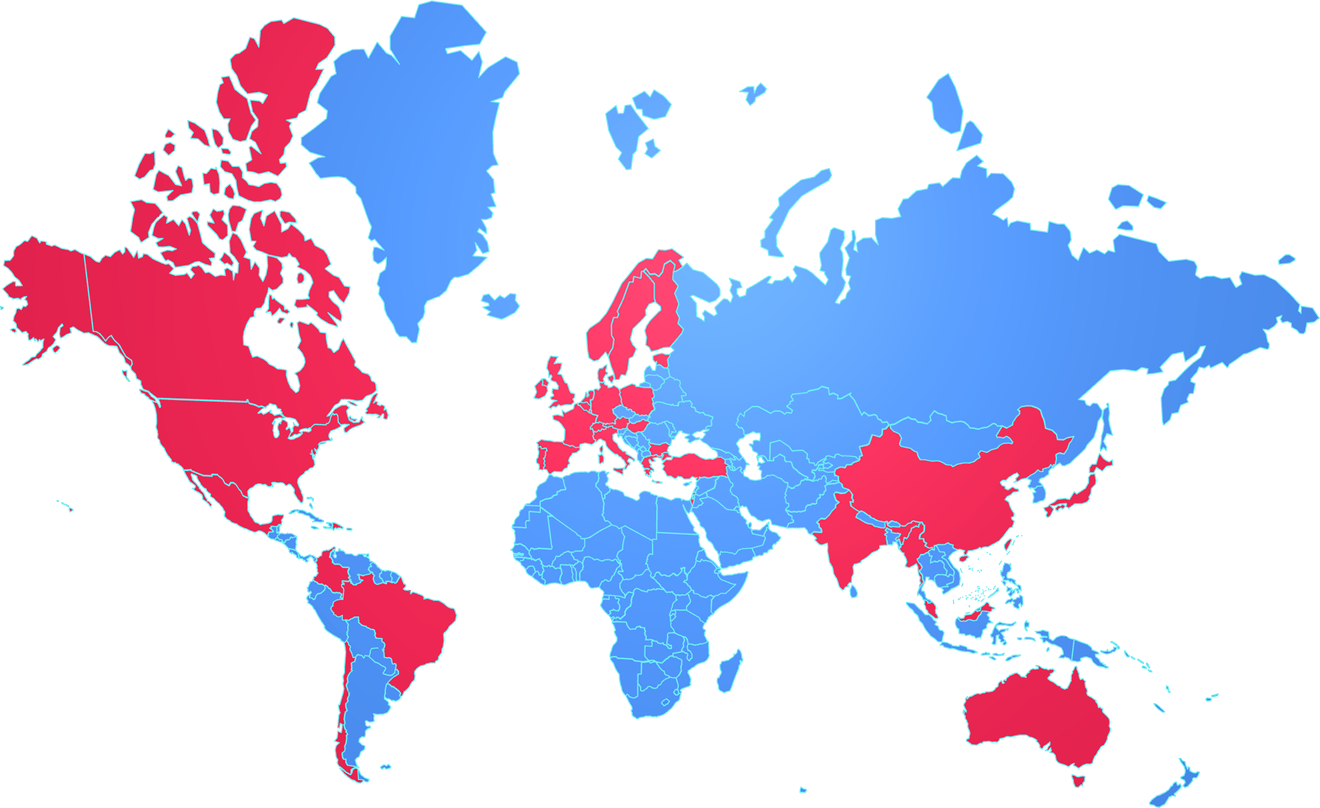

We were founded in 1992 as a Trading Company and distributor of Electronic components. In 1996, we started our fabrication and repacking sub-contracting house in Dongguan. From 2004, we consolidated our name as Emei Group and became a Leading manufacturer and supplier of EMI Gaskets, TIMs, Compounds and Adhesives, Bulk Molding Compounds and Specialty Transformers. We have four Business units with strong R & D and Supporting team in Dongguan, China. We have sales offices and manufacturing facilities in North America, Belgium, Hong Kong, Shanghai, and Taiwan. We have distributors in the USA, Mexico, Europe, the Middle East, and Japan.

-

-

-

1992

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Conductive foamThermal conduction gap filling padPolyFab foam

-

Assembly of motor/stepper motorFlexible circuit/membrane switchMedical equipment

-

Surface mount transformerPower inductanceSingle switch power supply

-

Medium voltage electricalLow voltage electricalHousehold appliances

-

-

Emei Group

Thermal Management Material

Thermal Management Material

| Typical applications | Products |

|

|

| Model no | Description | Characteristic | Viscosity cPs @25℃ | Curing Condition |

| 286A/B | Two component epoxy (white) | 2W/mK high thermal conductivity, 1:1 mixing ratio, Mixpac | paste | 25℃ 24hrs or 65℃ 2hrs |

| 282A/B | Two component epoxy (Gray) | 2W/mK high thermal conductivity, 1:1 mixing ratio, Mixpac | paste | 25℃ 24hrs or 65℃ 2hrs |

| 310-01 | One component epoxy | 4.2W/mK high thermal conductivity, high lap shear, black | 200K-300K | 150℃ 30mins or125℃ 60mins or reflow |

| 310-01HF | One component epoxy | 4.2W/mK high thermal conductivity, high lap shear, black | 200K-300K | 150℃ 30mins or125℃ 60mins or reflow |

| 310-01GHF | One component epoxy | 4.2W/mK high thermal conductivity, high lap shear, black, halogen free | 200K-300K | 150℃ 30mins or125℃ 60mins or reflow |

| 400-64-1AFR/600-9B | Two component epoxy | UL 94V-0,2.5W/mK high thermal conductivity, Low CTE | 60-90k(mixed) | 25℃ 16hrs or 65℃ 1hrs |

| 400-64-1AFR/600-11B | Two component epoxy | 2.5W/mK high thermal conductivity, low CTE | 60K-90K(mixed) | 120℃ 30mins |

| 400-64-1AFR/CAT GEL | Two component epoxy | 2.5W/mK high thermal conductivity, low hardness, low stress | 20K-30K(mixed) | 100℃ 3hrs or 125℃ 2hrs |

| 498-11A/B | Two component epoxy | 2.4W/mK high thermal conductivity, gray, room temperature curing | 10K-15K (mixed) | 25℃ 24hrs |

| 498-12A/B | Two component epoxy | 2.4W/mK high thermal conductivity, good adhesion, good out-gassing | 10K-15K (mixed) | 25℃ 24hrs |

| 318-9 | Thermal grease (silicone) | Thermal grease (silicone) | paste | |

| CAC-104 | Thermal grease (silicone) | 0.8W/mK high thermal conductivity | paste | |

| CAC106 | Thermal grease (silicone) | 2.0W/mK high thermal conductivity | paste | |

| 505-61 | Thermal grease (non-silicone) | 4.5W/mK very high thermal conductivity | paste | |

| CAC105-LV | Thermal grease (non-silicone) | 0.8W/mK high thermal conductivity | 100K | |

| E-Fill 3300 | Two component silicone | 1.5W/mK, low cost | 6K-9K | 80℃ 15mins or 25℃ 8hrs |

Add: No. 8 Qiaoxin Road, Qiaotou Town,

Tel:+ 86-769-83341628

Fax:+ 86-769-83342028

Email: emeidg@emeigroup.com

Website: http://www.emeigroup.com.cn