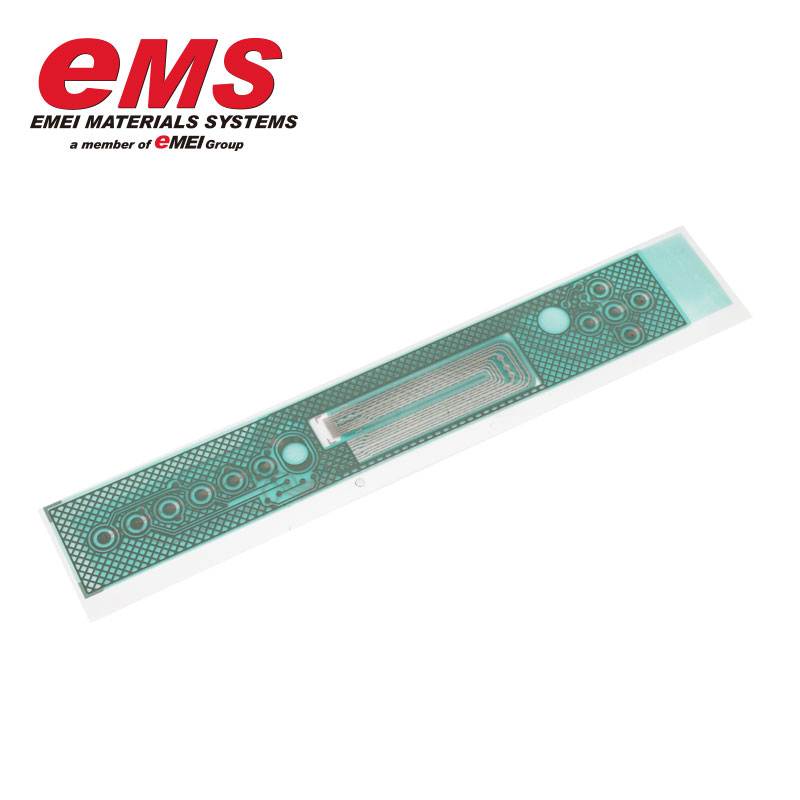

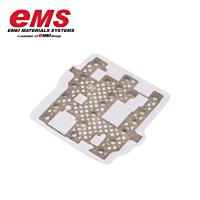

Membrane switch / FPC / RFID

Membrane switch / FPC / RFID

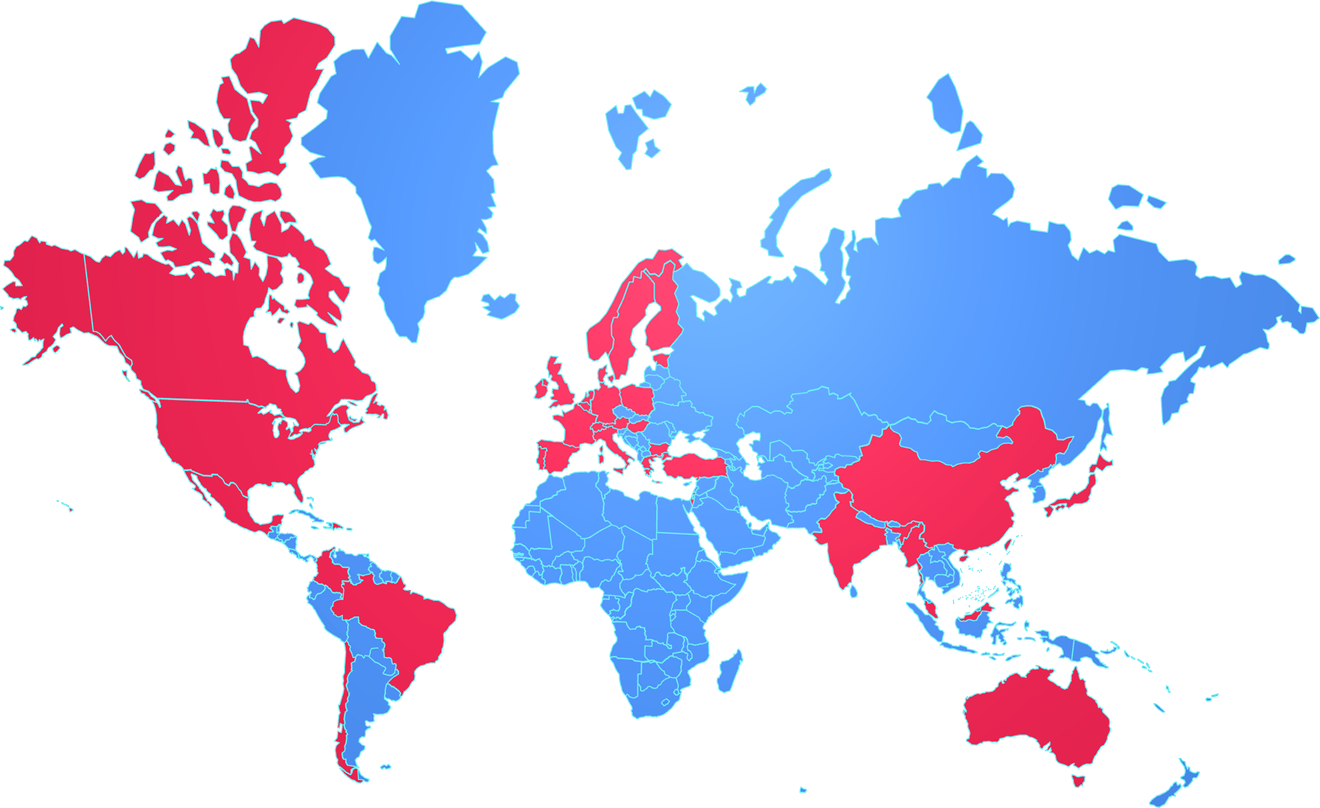

| Typical applications | Products |

|

|

| Model no | Description | Characteristic | Viscosity cPs @25℃ | Curing Condition |

| CI-1001 | Conductive silver ink | High conductivity | <0.015Ω/□.mil | 120℃ 20mins |

CI-1001B | Conductive silver ink | High conductivity, low cost | <0.015Ω/□.mil | 120℃ 20mins |

CI-1036 | Conductive silver ink | Very high conductivity, good flexibility and stretchable | <0.010Ω/□.mil | 110℃ 20mins |

| CI-1075 | Conductive silver ink | Good flexibility and elongation for IMD applications | <0.010Ω/□.mil | 120℃ 10mins |

| CI-1088 | Conductive silver ink | Low temperature curing | <0.025Ω/□.mil | 50℃ 10mins |

CI-800 | Conductive silver ink | High conductivity, good flexibility, good adhesion | <0.015Ω/□.mil | 120℃ 30mins |

| CI-801 | Conductive silver ink | Very high conductivity, fine line printing | <0.009Ω/□.mil | 130℃ 30mins |

| CI-804 | Conductive silver ink | For PC antenna printing | <0.010Ω/□.mil | 120℃ 30mins |

| CI-2001 | Conductive carbon ink | Abrasion resistance, for silver contacts | <20Ω/□.mil | 110℃ 20mins |

| CI-2001XL | Conductive carbon ink | Low viscosity for using with CI-2001 | Not to be used alone | 110℃ 20mins |

| CI-2018 | Conductive carbon ink | Fine line printing for zebra connectors | <12Ω/□.mil | 120℃ 30mins |

| CI-2018H | Conductive carbon ink | High viscosity, low resistance, for PCB | <11Ω/□.mil | 120℃ 30mins |

| CI-2018L | Conductive carbon ink | Low viscosity for using with CI-2018H | <50Ω/□.mil | 120℃ 30mins |

| CI-2002 | Conductive carbon ink for heater | For heater application, temperature resistant | <50Ω/□.mil | 110℃ 20mins |

| CI-2022 | Conductive carbon ink for heater | High electrical resistance, use with CI-2002 | <20kΩ/□.mil | 110℃ 20mins |

| CI-2050 | Conductive carbon ink | Pressure sensitive carbon ink | <22Ω/□.mil | 110℃ 10mins |

| CI-2051 | Conductive carbon ink | Stretchable carbon ink | <50Ω/□.mil | 90℃ 5mins |

| CI-2062 | Conductive carbon ink | Positive temperature coefficient carbon ink | <50Ω/□.mil | 90℃ 5mins |

| CB-F1023 | Conductive carbon ink | For ITO connection in LCD | <15Ω/□.mil | 80℃ 15mins |

| DI-7502 | UV curing dielectric | General purpose UV dielectric | >800V/mil | 750mJ/cm² |

| DI-7502B | UV curing dielectric | Blue version of DI-7502 | >800V/mil | 750mJ/cm² |

| DI-7502C | UV curing dielectric | Clear version of DI-7502 | >800V/mil | 750mJ/cm² |

| DI-7502LH | UV curing dielectric | Halogen free, light green version of DI-7502 | >800V/mil | 750mJ/cm² |

| DI-702 | UV curing dielectric | Low cost dielectric for general purposes | >800V/mil | 750mJ/cm² |

| DI-702C | UV curing dielectric | Clear version of DI-702 | >800V/mil | 750mJ/cm² |

| DI-7544 | UV curing dielectric | Resistant to high temperature and humidity | >800V/mil | 750mJ/cm² |

| D04-132 | UV curing spacer | For space printing, high viscosity | >800V/mil | 750mJ/cm² |

| DI-701 | Heat curing dielectric, green | General purpose, heat curing | >800V/mil | 130℃ 20mins |

| DI-701C | Heat curing dielectric, clear | Good adhesion to ITO, good compatibility with various silver inks | >800V/mil | 130℃ 20mins |

| DA-5100 | LED surface mount silver epoxy | Very good adhesion | <0.0006 Ω.cm | 130℃ 90mins |

| EC-9519 | LED encapsulant | UV curing, low stress, elastic | >800V/mil | 750mJ/cm² |

Outstanding Stability

EMS CI-1001 shows outstanding stability over Shanghai and China competitors. Please see the below for the conductivity change over time after curing:

Applicable to:

Product Center