-

-

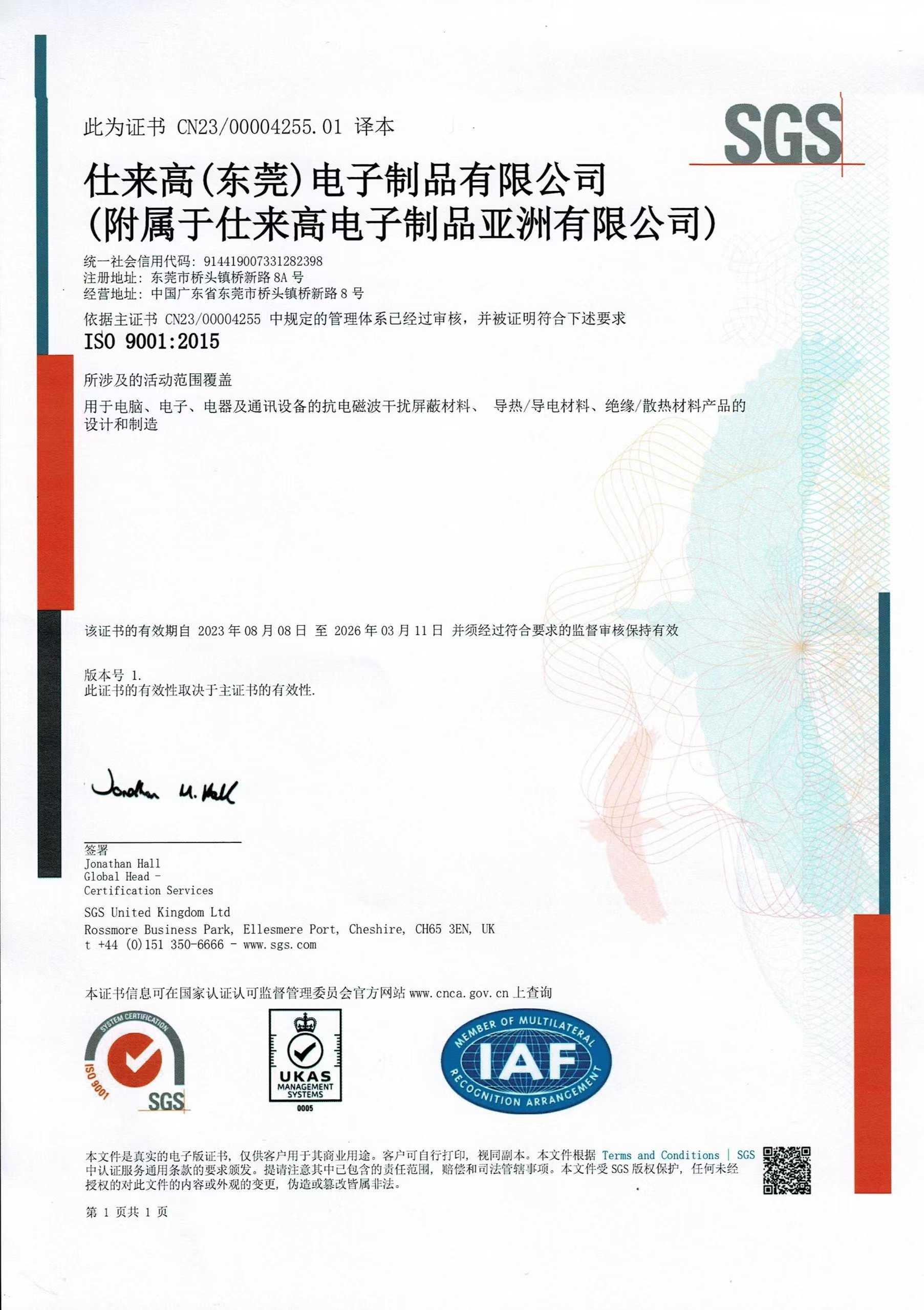

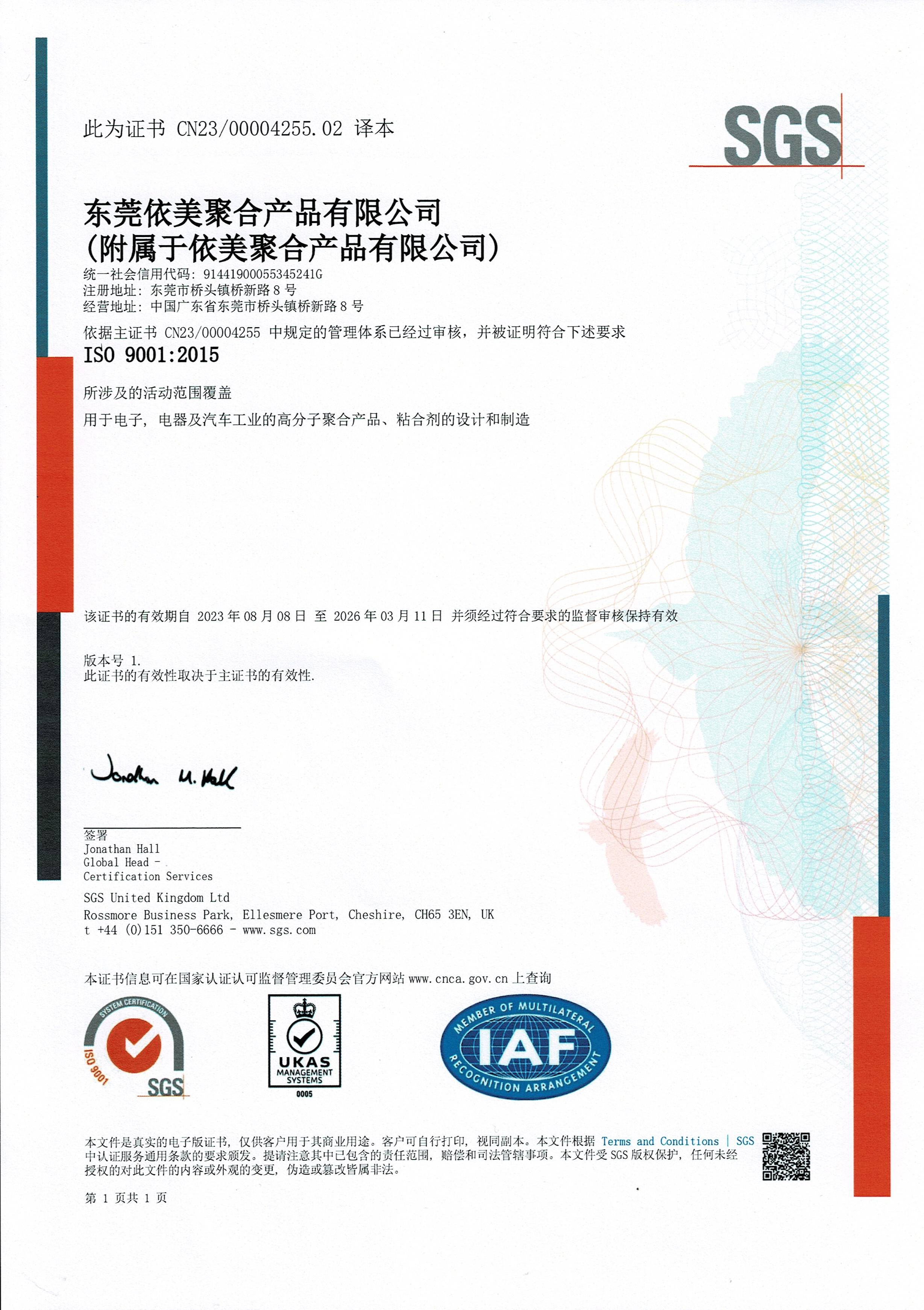

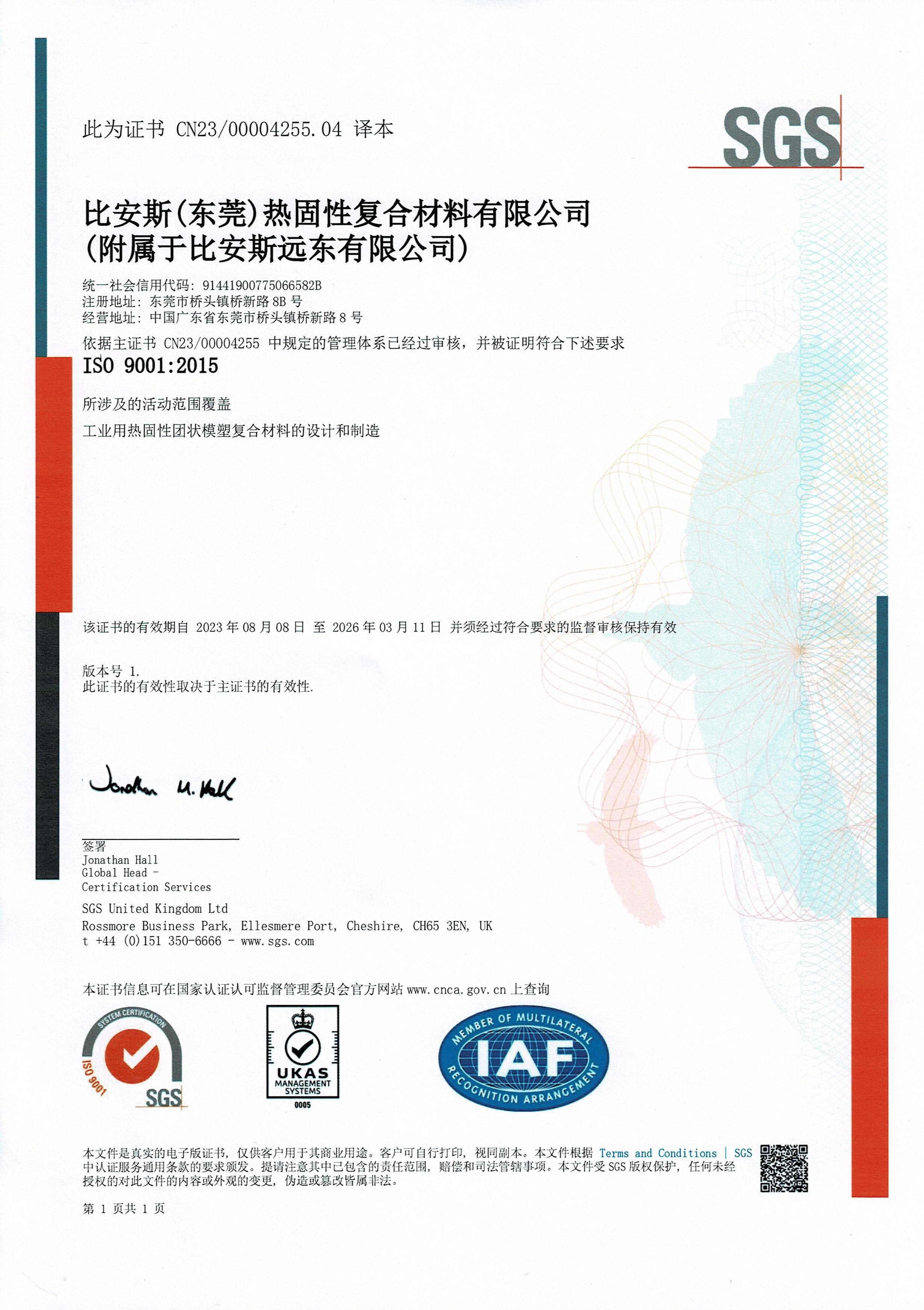

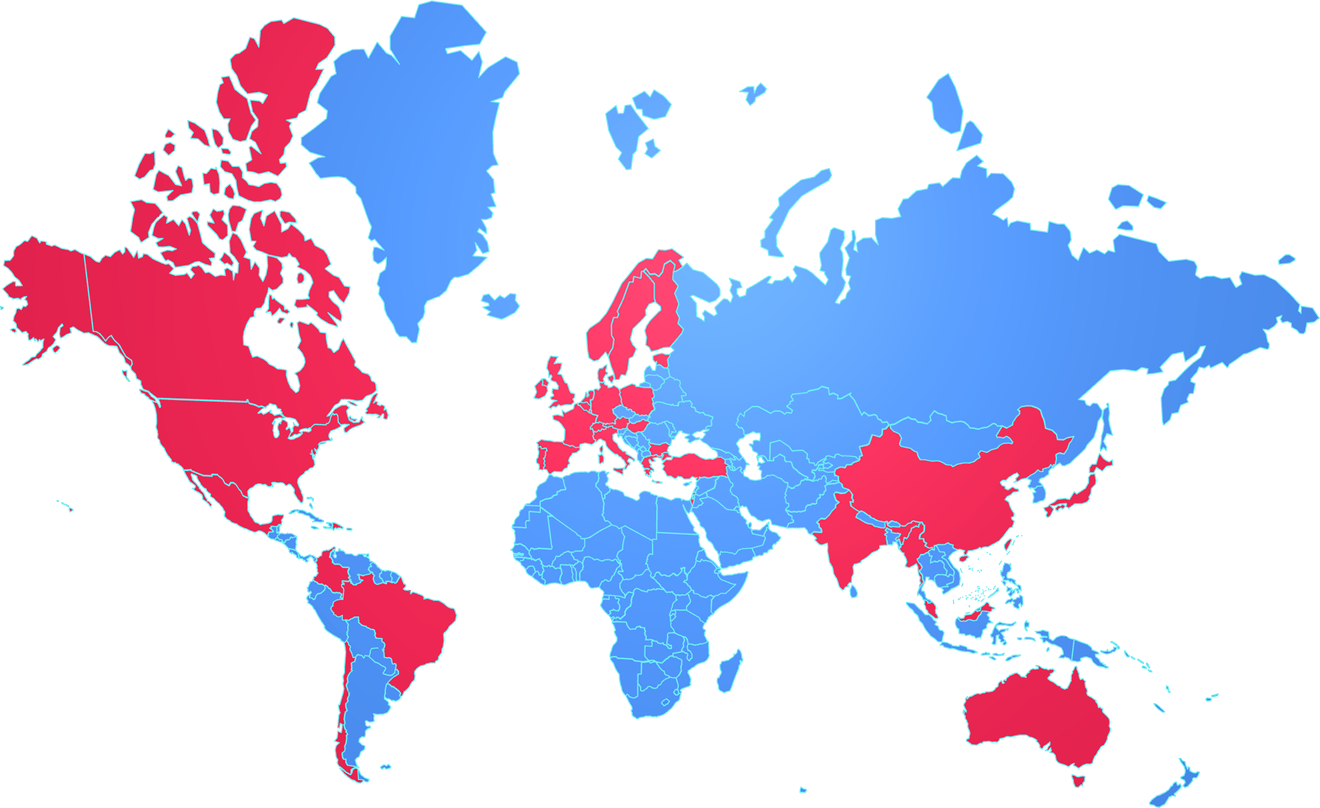

We were founded in 1992 as a Trading Company and distributor of Electronic components. In 1996, we started our fabrication and repacking sub-contracting house in Dongguan. From 2004, we consolidated our name as Emei Group and became a Leading manufacturer and supplier of EMI Gaskets, TIMs, Compounds and Adhesives, Bulk Molding Compounds and Specialty Transformers. We have four Business units with strong R & D and Supporting team in Dongguan, China. We have sales offices and manufacturing facilities in North America, Belgium, Hong Kong, Shanghai, and Taiwan. We have distributors in the USA, Mexico, Europe, the Middle East, and Japan.

-

-

-

1992

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Conductive foamThermal conduction gap filling padPolyFab foam

-

Assembly of motor/stepper motorFlexible circuit/membrane switchMedical equipment

-

Surface mount transformerPower inductanceSingle switch power supply

-

Medium voltage electricalLow voltage electricalHousehold appliances

-

-

Emei Group

Emei Group is a supplier of electronic engineering materials and components

Motor/ Stepper Motor Assembly

Motor/ Stepper Motor Assembly

| Typical applications | Products |

|

|

| Model no | Description | Characteristic | Viscosity cPs @25℃ | Curing Condition |

| 180-08A/B | Two component step motor rotor coating | High temperature resistance, green | 60K (mixed) | 150℃ 120mins |

| 400-36G | One component step motor rotor coating | High temperature resistance, green | 30K | 150℃ 120mins |

| 702-80 | Neck glue for commutator wiring protection | High temperature resistance, corrosion resistance | paste | 120℃ 30mins |

| 702-80-140K | Neck glue for commutator wiring protection | High temperature resistance, corrosion resistance, low viscosity | 140K | 120℃ 30mins |

| 505-96 | Neck glue for commutator wiring protection | Very high temperature resistance ,high Tg 220℃ | Paste | 160℃ 30mins |

| 702-98 | Epoxy adhesive for magnet bonding | Induction curable | paste | Induction curing or 120℃ 40mins |

| 400-76-1 | Epoxy adhesive for magnet bonding | Very low viscosity | 80K | 120℃ 45mins |

| DA-5193 | Conductive epoxy for carbon brush | Excellent adhesion to copper and graphite | 8K-10K | 150℃ 30mins |

P2T/SC | Two component magnet bonding acrylate adhesive | Good adhesive, fast curing | 8K-10K | 25℃ < 1min |

Applicable to:

Product Center

Service Hotline

Emei Group

Product Center

Our business

Follow us

Contact address

86-769-83341628

Chinese Mainland: No. 8, Qiaoxin Road, Qiaotou Town,

Dongguan City, Guangdong Province

Hong Kong, China: Room 1, 3rd Floor, Block A, New Trade Centre,

6 On Ping Street, Sha Tin, New Territories, Hong Kong

Telecommunications fieldSolution

Advanced electronic device application solutions

Application solutions in the field of automobile manufacturing

Medical field solutions

Electrical Application Solutions

Building Material Solutions

Lighting industry solutions

Emei Group

Add: No. 8 Qiaoxin Road, Qiaotou Town,

Add: No. 8 Qiaoxin Road, Qiaotou Town,

Dongguan City, Guangdong Province

Tel:+ 86-769-83341628

Fax:+ 86-769-83342028

Email: emeidg@emeigroup.com

Website: http://www.emeigroup.com.cn

Tel:+ 86-769-83341628

Fax:+ 86-769-83342028

Email: emeidg@emeigroup.com

Website: http://www.emeigroup.com.cn